In metal fabrication, precision and efficiency are key to producing high-quality components. One critical process that demands both is blanking—a method where a flat piece of material, known as a blank, is cut from a larger sheet or strip of metal. At Vansh Industries, we understand the importance of this process, which is why we offer advanced Hydraulic H-type presses designed to optimize your blanking operations.

What is Blanking?

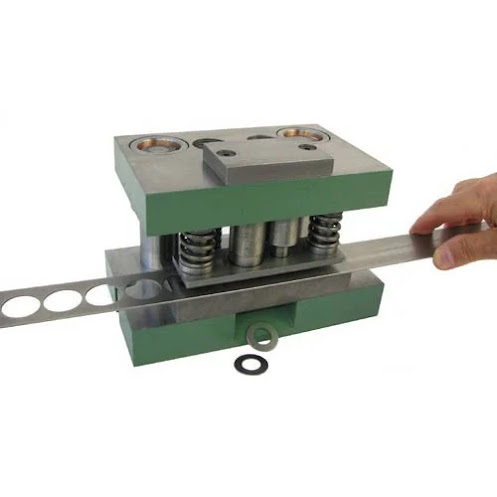

Blanking is a metalworking process where a punch and die are used to shear a piece of material from a larger sheet, creating a "blank." This blank can then be further processed or used as a final product. The blanking process is crucial in automotive, electronics, and manufacturing industries, where it’s used to produce components like gears, washers, brackets, and more.

The Blanking Process: How It Works

1. Material Feeding: The process begins by feeding a metal sheet or strip into a press machine that holds the punch and die set.

2. Punch and Die Alignment: The punch (upper tool) and die (lower tool) are aligned to match the shape of the blank to be cut.

3. Cutting Action: The press is activated, and the punch moves down with force, shearing the material against the die and cutting out the blank.

4. Blank Ejection: The blank is then ejected or falls away from the die, leaving behind scrap material, which is typically recycled.

5. Repeat Cycle: The process is repeated for each blank until the entire sheet or strip is processed.

Types of Blanking Operations Supported by Vansh Industries' Hydraulic H-Type Presses

Our Hydraulic H-Type Presses are versatile and can be used for various types of blanking operations, including:

- Conventional Blanking: A standard method where the blank is cut in a single press stroke.

- Fine Blanking: A precision method that uses a triple-action press for clean cuts with minimal burrs, ideal for intricate parts.

- Progressive Blanking: A sequence of operations within the same press to produce multiple blanks efficiently.

- Compound Blanking: Combines blanking with other processes like piercing or bending in a single stroke, increasing productivity.

- Punching and Blanking: Involves cutting holes or slots in the blank as it's being cut from the sheet.

- Parting Blanking: Separates the blank entirely from the scrap material, making it ready for immediate use or further processing.

Why Choose Vansh Industries' Hydraulic H-Type Press?

1. 💪 High Precision: Our presses deliver consistent force distribution, ensuring clean, accurate cuts and high-quality blanks.

2. ⚙️ Robust Design: Built to handle heavy-duty operations, our presses are reliable and long-lasting, even in the most demanding environments.

3. 🔄 Versatile Applications: Suitable for blanking various materials, from thin metal sheets to thicker automotive components.

4. 🛡️ Safety First: Our presses are equipped with advanced safety features to protect your operators and ensure a secure working environment.

5. 💡 Energy Efficiency: Designed to minimize energy consumption, our presses help reduce operational costs while maintaining peak performance.

Applications Across Various Industries

- 🏭 Automotive Manufacturing: Ideal for creating precision parts like gears, brackets, and gaskets.

- 🔩 Metal Fabrication: Perfect for cutting metal sheets with high accuracy and minimal waste.

- 📦 Packaging Industry: Efficient in blanking materials used for packaging, ensuring consistency and quality.

- ⚙️ Engineering Applications: Provides the precision needed for complex engineering components.

The Vansh Industries Advantage

At Vansh Industries, our mission is to provide innovative machinery solutions that meet the specific needs of our customers. Our **Hydraulic H-Type Presses** are engineered to enhance the efficiency, precision, and profitability of your blanking operations, making them an essential addition to any production line.

Contact Us Today

Are you ready to elevate your blanking operations? Contact us today for more information or to request a quote. Let Vansh Industries be your partner in achieving excellence in metal fabrication.

📞 Phone: +91-6934240075

📧 Email: vanshindustresi.com.gmail.com

🌐 Website: www.vanshindustries.net

Join us in revolutionizing your manufacturing process with the power of precision and reliability!

%20(94).png)

No comments:

Post a Comment