Deep Draw Hydraulic Press Machine – Shaping the Future of Metal Forming | Vansh Industries

Vansh Industries stands at the forefront of precision engineering, offering high-performance Deep Draw Hydraulic Press Machines designed for manufacturing complex, deep-formed metal components. Our commitment to quality, innovation, and customer satisfaction has made us a trusted name across India and overseas in the field of hydraulic press manufacturing.

What Is a Deep Draw Hydraulic Press?

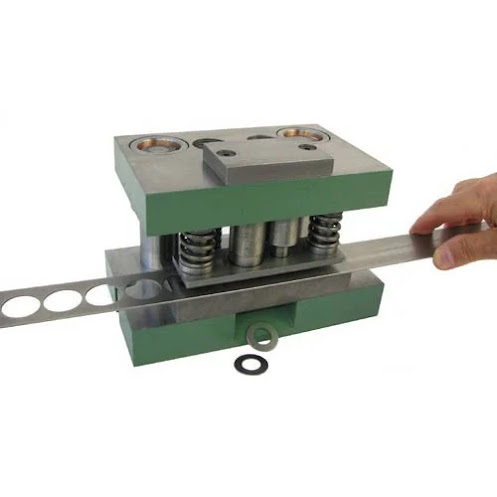

A Deep Draw Hydraulic Press Machine is an advanced metal forming solution that reshapes flat metal blanks into hollow, three-dimensional components. This is achieved by hydraulically pressing the sheet metal into a die using high pressure and control.

This technique is ideal for producing deep, intricate components that would be challenging to manufacture with traditional processes like stamping or bending. The method works with various metals such as steel, aluminum, brass, and copper, making it suitable across industries including automotive, aerospace, medical, and consumer appliances.

How Does It Work?

The process begins with a flat sheet of metal, known as a blank, placed over the cavity of a specially designed die. A hydraulic ram gradually applies pressure to a punch, guiding the metal blank into the die cavity.

Unlike mechanical presses, hydraulic deep draw presses from Vansh Industries offer superior pressure control, allowing deeper and more complex shapes to be formed without tearing or compromising the integrity of the metal. The slow and steady application of pressure enhances accuracy and material strength, especially for parts that require high durability.

Key Advantages of Vansh Deep Draw Hydraulic Press Machines

✅ Versatile Design Capabilities

Our presses can create highly intricate, deep-drawn parts from a single metal sheet, reducing part count, simplifying assembly, and minimizing production steps.

✅ High Accuracy and Uniformity

The hydraulic system ensures consistent pressure and forming accuracy, critical in industries like aerospace and medical, where even minor deviations are unacceptable.

✅ Optimized Material Usage

Deep drawing allows maximum utilization of each metal blank, which reduces material waste and contributes to cost-efficiency in large-scale production.

✅ Enhanced Strength and Structural Integrity

Cold working during deep drawing increases the strength of the final product—ideal for automotive and industrial applications where durability is non-negotiable.

✅ Cost-Effective Production

By reducing the need for welding, joints, and additional processing, our machines streamline production, enabling quicker output at lower operating costs.

✅ Environmentally Friendly

Hydraulic systems consume less energy, and better material utilization means reduced waste—supporting sustainable manufacturing goals.

Industry Applications

Our Deep Draw Hydraulic Press Machines serve a wide range of industries:

-

🚗 Automotive: Fuel tanks, wheel rims, clutch housings, transmission covers

-

✈️ Aerospace: Lightweight structural parts, engine casings, airframe components

-

🏠 Consumer Appliances: Cookware, sink bowls, appliance housings

-

⚡ Electrical: Enclosures, switchgear boxes, transformer shells

-

🏥 Medical: Surgical trays, equipment casings, sterilization containers

Why Choose Vansh Industries?

🏭 Decades of Manufacturing Expertise

Founded in 2014 in Dehradun, Uttarakhand, Vansh Industries has been a key player in hydraulic solutions and turnkey project deliveries for LPG Cylinder plants and other specialized machinery.

🛠️ Advanced Infrastructure

We boast a modern manufacturing facility equipped with CNC machines, precision tools, and quality testing units that ensure our presses meet the highest standards.

⚙️ Customized Engineering Solutions

From standard to fully customized presses, we cater to the unique requirements of our clients with a flexible and collaborative approach.

🔧 Robust After-Sales Support

Our relationship doesn’t end with the sale. We offer on-site installation, training, maintenance, and lifetime technical support to ensure smooth operation.

🌐 Global Presence

Vansh Industries proudly serves clients across India and exports to countries like Saudi Arabia, building a global reputation for quality and reliability.

Conclusion

The Deep Draw Hydraulic Press Machine is more than just a tool—it's a complete solution for modern metal forming challenges. With the ability to deliver durable, cost-effective, and precision-engineered components, it is revolutionizing production in multiple industries.

At Vansh Industries, we don’t just manufacture machines—we engineer performance, reliability, and long-term value. When you choose Vansh, you choose a partner dedicated to your success.

📞 Contact Us Today

Vansh Industries, Dehradun, Uttarakhand

📧 Email: [info@vanshindustries.com]

📞 Phone: +91-9634240075

🌐 Website: www.vanshindustries.co.in

%20(89).png)

.png)

%20(80).png)

%20(56).png)

%20(65).png)

%20(23).png)

%20(19).png)

%20(12).png)

%20(13).png)

.png)

.png)

.JPG)

.png)

%20(94).png)

%20(56).png)