Vansh Industries stands at the forefront of India’s industrial machinery sector, delivering turnkey plant solutions, precision hydraulic systems, and bespoke special-purpose machines that empower manufacturers to achieve higher productivity, quality, and sustainability. Leveraging over a decade of engineering excellence, in-house R&D, and end-to-end project management, Vansh Industries transforms complex production challenges—ranging from LPG cylinder fabrication (4 kg–425 kg) to heavy-duty metal forming—into reliable, scalable operations. Their commitment to innovation, rigorous quality control, and comprehensive after-sales support makes them a trusted partner for clients across India and international markets.

Company Overview

Vansh Industries, founded in 2014 in Dehradun, Uttarakhand, has built a reputation as a technology-driven manufacturer of industrial machinery. Based on Pascal’s law, their hydraulic systems deliver uniform, high-tonnage force for tasks from deep drawing to rim-tyre separation; their LPG cylinder plants adhere to BIS standards; and their special-purpose machines (SPMs) automate niche operations with precision and speed.

Core Products & Services

1. Turnkey LPG Cylinder Manufacturing Plants

-

Scope: Plant design, equipment supply, civil erection, piping, electricals, commissioning, and training.

-

Range: Cylinders from 4 kg (camping/emergency) up to 425 kg bulk skids.

-

Compliance: Built to BIS 4093 specifications, with automatic testing and PLC-controlled bottling lines for safety and throughput.

2. Hydraulic Presses

-

Types: Deep Drawing (die-cushioning, blank-holding), C-Frame, H-Frame, and Four-Column presses.

-

Applications: Metal forming, molding, punching, laminating, and specialized tyre-rim separation fixtures.

-

Market Growth: Global hydraulic press market projected to reach US$21 billion by 2025 at 4.7% CAGR, driven by automotive and metalworking demand.

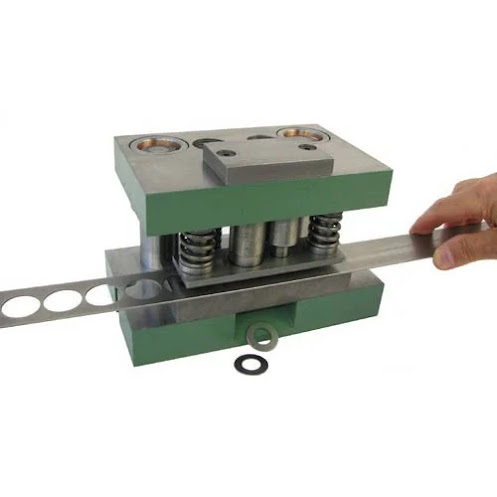

3. Special Purpose Machines (SPMs)

-

Customization: Machines built for dedicated tasks—joggling, welding, trimming, beading—in LPG, automotive, and fabrication sectors.

-

Efficiency: SPM market growing at 6.8% CAGR with demand for automated, high-precision production lines.

4. Hydraulic Power Packs & Systems

-

Components: Power-pack units, cylinders, valves, and piping, all engineered for optimal energy efficiency and reliability in harsh industrial environments.

Vision, Mission & Values

-

Vision: To be the market leader in hydraulic and LPG cylinder machinery, setting benchmarks in innovation, quality, and sustainability.

-

Mission: Deliver customer-centric, eco-friendly solutions that create value, generate employment, and foster technological advancement.

-

Core Values: Integrity, precision, continuous improvement, and holistic support—from concept to lifecycle maintenance.

Achievements & Milestones

-

Rapid Plant Commissioning: Executed a complete LPG cylinder plant layout, approvals, machinery, and commissioning in just 120 days, showcasing project management excellence.

-

500+ Machines Supplied: Over a decade, delivered hundreds of hydraulic presses, SPMS, and turnkey installations across India and to overseas clients in Africa and South Asia.

Why Partner with Vansh Industries?

-

End-to-End Solutions: Single-source for design, manufacturing, installation, and after-sales service.

-

Customized Engineering: Machines tailored to your product specifications and production targets.

-

Quality Assurance: ISO-grade processes, rigorous testing, and adherence to international standards.

-

Sustainable Practices: Energy-efficient hydraulics and waste-minimizing production methods.

-

Global Reach: Proven track record in domestic and export markets, backed by responsive support.

Elevate your manufacturing with precision-engineered machinery from Vansh Industries, where innovation meets reliability.

%20(74).png)

.png)

%20(17).png)

.JPG)

.png)

%20(94).png)

%20(56).png)